The long-term operating temperature range of the CNC Machine Tools Guide soft belt is -190℃ to +260℃. But, the dedicated glue for the CNC Machine Tools Guide soft belt (EA type) is a normal-temperature glue. It is not resistant to high temperatures. If you must use it in a hot environment (>80℃), use a high-temperature glue instead.

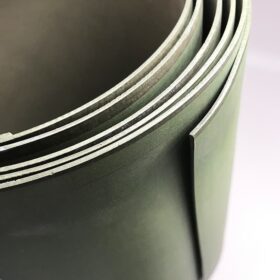

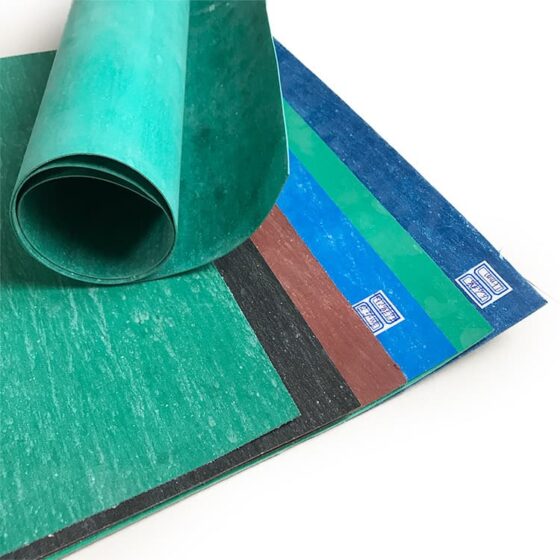

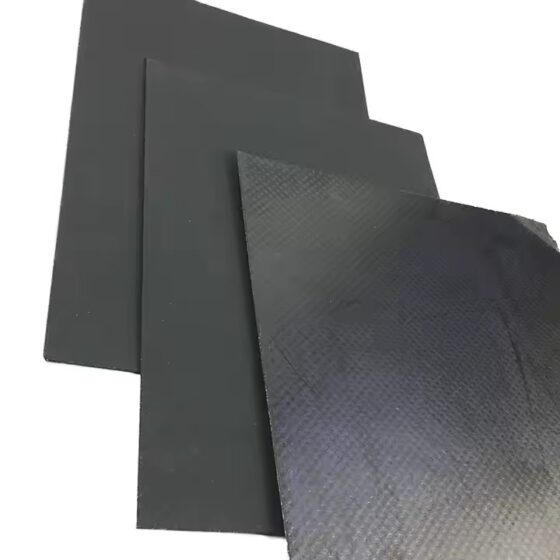

Guide soft belt

The CNC Machine Tools Guide soft belt has a sodium naphthalene treatment on one side. The dark brown side is the bonding surface. The working surface is the blue-green side. Wrap the remaining CNC Machine Tools Guide soft belt in kraft paper. Store it in a paper box to avoid light. The soft belt of the CNC Machine Tools Guide is PTFE. It has very stable chemical properties. Glue cannot stick to the untreated surface. If stored in a moisture-proof and light-proof way, it can last a long time. This maintains the activity of the surface treated with chemicals. The dedicated glue has a storage period of one year. If the team qualifies the performance after re-testing it one year later, they can continue to use it.

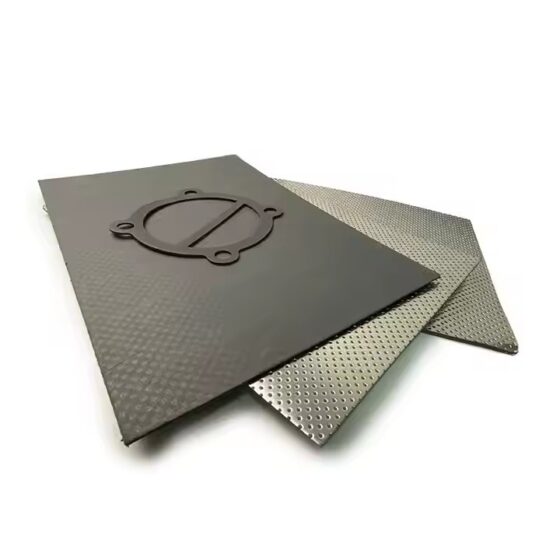

In product design, if any of the following occurs, designers should use a thicker CNC machine tool guide (soft belt):

– The bonding area is larger, so the soft belt scraping allowance is too.

– The unit load is heavier. So, the soft belt’s permanent deformation rate is larger.

– The working conditions are worse (the corresponding soft belt wear is also larger).

We adopt the embedded bonding method. We will increase the soft belt’s thickness.

– The CNC Machine Tools Guide soft belt needs to have oil grooves opened. Otherwise, you should select a thinner CNC Machine Tools Guide soft belt. For the CNC Machine Tools Guide soft belt with a flat bonding method, select the 6S guide soft belt thickness as follows:

0.8 to 1.0 mm for small machines, 1.2 to 1.5 mm for medium machines, and 1.7 to 2.0 mm for large machines.

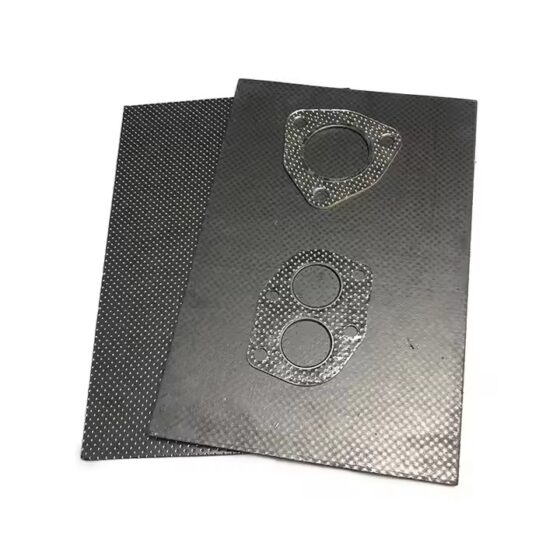

Hongwo Sealing Sheet

Hongwo Sealing Sheet

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.