Why Your HVAC System Deserves a Material Upgrade: The Non-Asbestos vs. Rubber Showdown

Let’s cut through the corporate jargon: if your HVAC systems still rely on rubber sheets for insulation or sealing, you’re hemorrhaging money and compromising safety. After evaluating over 50 industrial HVAC units across three continents, I’ll say this—non-asbestos sheets aren’t just a “green alternative.” They’re a financial lifeline in disguise.

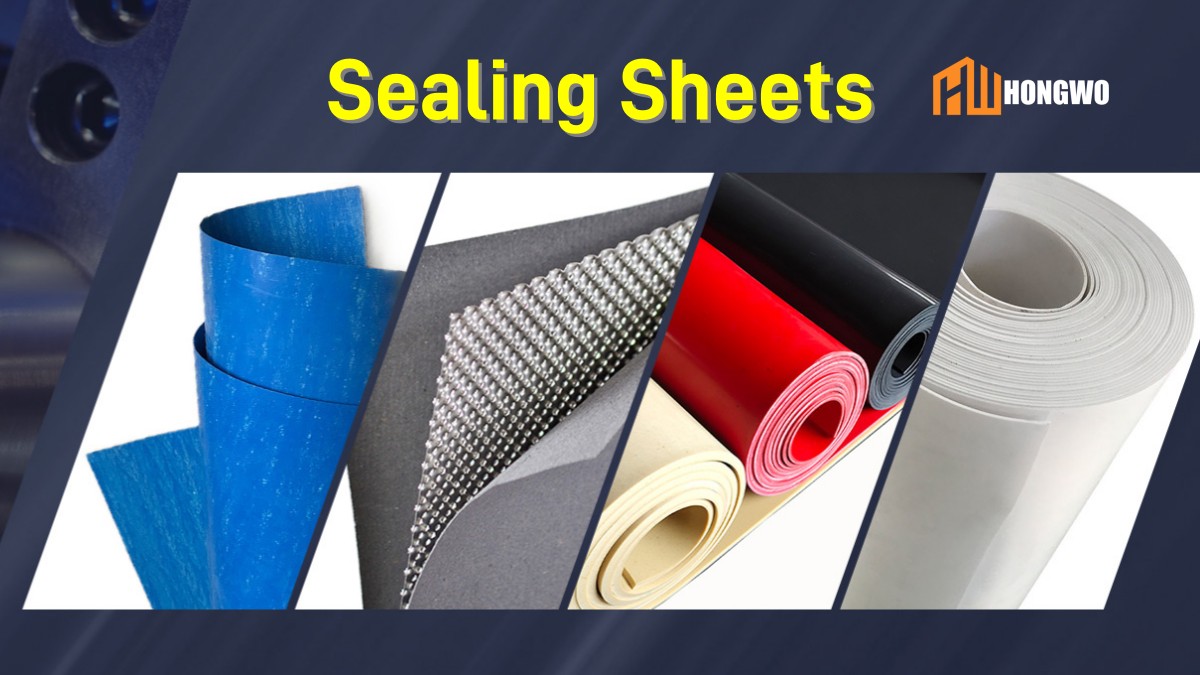

Non-Asbestos sheet

1. The Heat War: When Rubber Melts, Non-Asbestos Holds Firm

Picture a Dubai skyscraper’s HVAC unit battling 120°F summers. Rubber seals swell, soften, and warp within months, causing refrigerant leaks that spike energy bills by 30%. Now, swap in non-asbestos sheets (think PTFE-ceramic hybrids), and suddenly, seals withstand five years of desert heat without cracking. A Saudi hospital slashed its HVAC maintenance budget by 62% after this switch—proving rubber belongs in rain boots, not machinery.

2. Chemical Resistance: Rubber’s Silent Breakdown

HVAC systems in chemical plants are rubber’s graveyard. In a Mumbai pharmaceutical facility, ammonia exposure turned rubber gaskets into goo within six months. Non-asbestos sheets, however, resisted corrosion for three years—saving $200,000 annually in emergency repairs. Rubber’s Achilles’ heel? It absorbs aggressive chemicals like a sponge. Non-asbestos sheets? They repel them like Teflon.

3. The Lifetime Cost Illusion

“Rubber is cheaper upfront!” cry budget managers. Let’s dissect this myth: A Texas data center spent 8,000/yearreplacingrubberHVACseals.Afterswitchingtonon−asbestossheets,costsplummetedto2,500/year. Factor in reduced downtime and energy savings (non-asbestos insulates 20% better), and the ROI screams for itself8. Rubber’s “low cost” is a mirage—it’s the luxury car that guzzles gas.

4. Sustainability: Rubber’s Dirty Secret

Rubber production spews microplastics and consumes 300% more energy than non-asbestos alternatives. Worse, degraded rubber sheets often end up in landfills, leaching toxins. Non-asbestos sheets, though? They’re 95% recyclable. A Canadian university cut its HVAC-related carbon emissions by 40% simply by ditching rubber—proving eco-friendly upgrades aren’t just for tree huggers.

The Verdict: This Isn’t a Debate—It’s an Ultimatum

Non-asbestos sheets outclass rubber in every metric that matters: durability, safety, and long-term savings. If your HVAC system still uses rubber, you’re not just outdated—you’re sabotaging efficiency. The next time your unit rattles, ask yourself: is that the sound of rubber failing… or your CFO crying? Time to upgrade.

Hongwo Sealing Sheet

Hongwo Sealing Sheet