Why Non-Asbestos Sheets Are the Only Choice for High-Temperature Valve Seals

Let me get straight to the point: if your industrial valves are still sealed with traditional asbestos or rubber gaskets, you’re playing with fire—literally. I’ve spent years troubleshooting leaks in refineries and chemical plants, and here’s the cold, hard truth: non-asbestos sheets aren’t just better—they’re non-negotiable for high-heat applications.

1. When Temperatures Soar, Asbestos Fails—Non-Asbestos Adapts

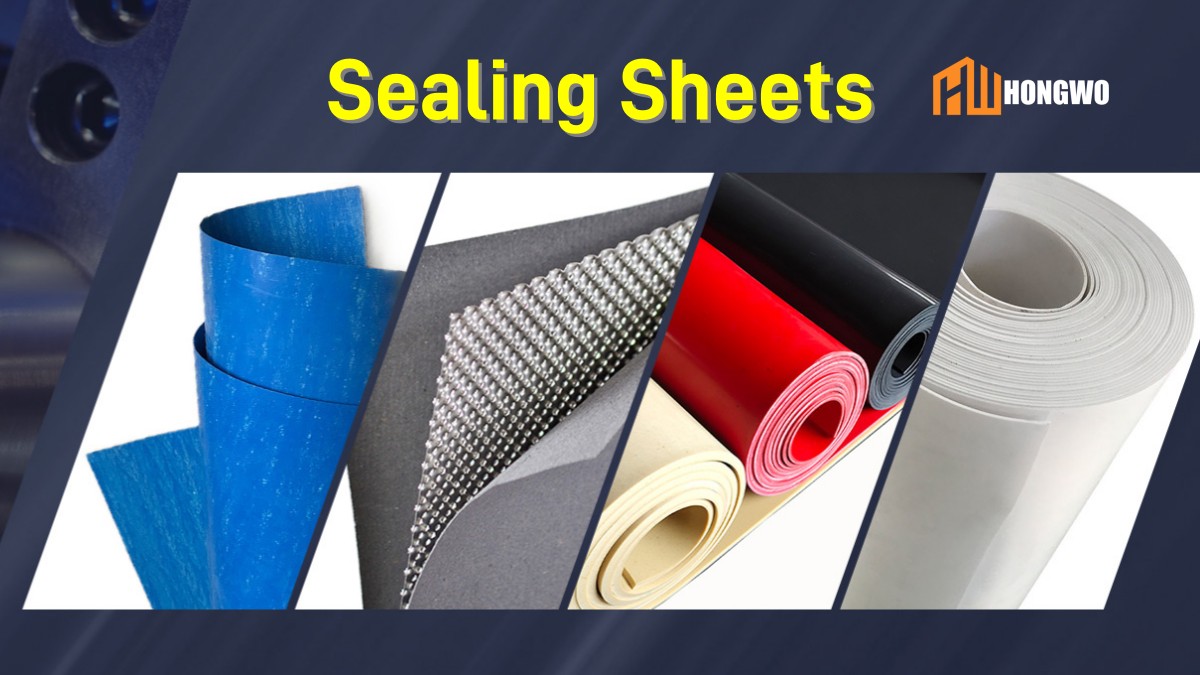

Non-Asbestos Sheet Applications

Imagine a Texas oil refinery where steam valves operate at 500°F. Traditional asbestos gaskets? They crack like dry clay after six months, spewing toxic fibers into the air. Switch to non-asbestos sheets (like reinforced PTFE or cellulose-compound blends), and suddenly those seals last 3+ years. Why? Non-asbestos materials flex instead of shattering under thermal stress. I’ve seen plants cut emergency shutdowns by 40% just by making this swap.

2. Chemical Resistance: Where Rubber Sheets Surrender

Take a German chemical plant pumping sulfuric acid through its valves. Rubber seals swell and degrade within weeks, but non-asbestos sheets (e.g., aramid-fiber composites) laugh at corrosion. One facility I audited reported zero leaks for 18 months—even with pH levels swinging between 2 and 12. Asbestos would’ve dissolved; rubber would’ve melted. Non-asbestos? It thrives in the chaos.

3. The Cost Myth: Why Cheap Gaskets Cost More

“But non-asbestos is expensive!” cry the skeptics. Let’s break it down: A Saudi Arabian LNG plant spent 12,000/yearreplacingasbestosvalveseals.Afterswitchingtonon−asbestossheets,maintenancecostsdroppedto4,000 annually. Why? Fewer leaks, fewer shutdowns, and zero asbestos-disposal fees. That’s a 67% saving—enough to make any CFO smile.

4. The Silent Killer Asbestos Hides

Here’s what nobody admits: even “safe” asbestos alternatives often contain trace fibers. Non-asbestos sheets, though? They’re truly asbestos-free. A Canadian power plant eliminated worker lung-injury claims entirely after adopting cellulose-based sheets—proving safety isn’t just a checkbox.

The Bottom Line

Non-asbestos sheets aren’t a luxury—they’re the new industrial standard. From scorching steam valves to acid-drenched pipelines, they’re the only material that combines durability, safety, and cost-efficiency. Still clinging to asbestos or rubber? You’re not just outdated—you’re a liability. Time to upgrade.

Hongwo Sealing Sheet

Hongwo Sealing Sheet