Rubber materials are key engineering materials. They are widely used in water conservancy projects. Oil-resistant, asbestos-free rubber sheets are a new rubber material. They are gaining more attention and use in water conservancy projects. This article reviews how effective oil-resistant, asbestos-free rubber sheets are in water conservancy projects.

1. Main uses are sealing, waterproofing, sound insulation, and reducing vibrations in water conservancy projects. Specific applications include, but are not limited to, the following aspects:

1.1 It seals very well. You can use it for pipes, valves, pump stations, and other equipment in water projects. It stops water leaks and keeps out impurities. This helps to ensure smooth operation in water conservancy projects.

1.2 It has great water resistance. You can use it for waterproofing buildings and engineering structures. This includes reservoirs, dams, and ports in water conservancy projects. Laying rubber sheets prevents water seepage and damage to drainage systems. This protects the safety and stability of engineering structures.

1.3 Its elasticity and sound absorption make it perfect for sound insulation in water projects. It works well for sound insulation in pump rooms, generator rooms, and similar spaces. It cuts down noise from machines. This makes the work environment quieter and more comfortable for everyone.

1.4 Vibration reduction material

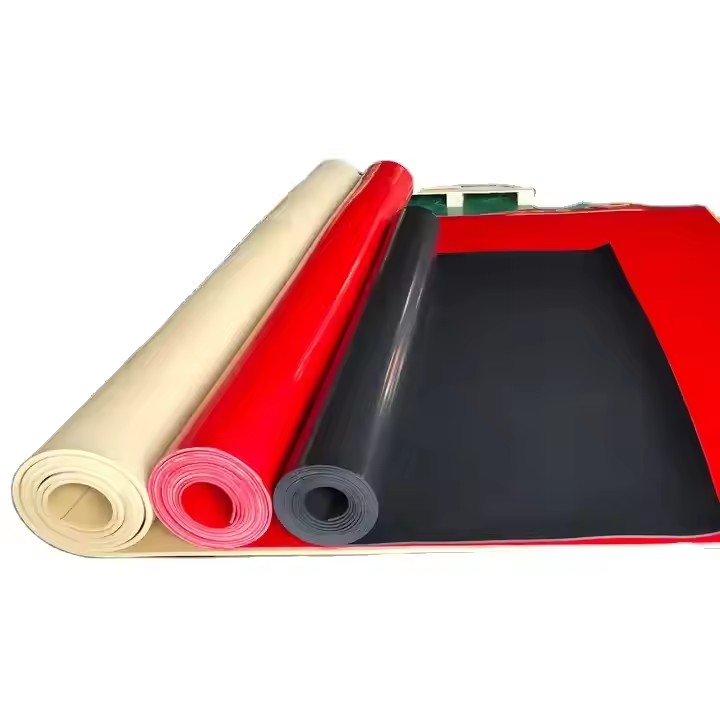

Oil-resistant Non-Asbestos Rubber Sheets

It has great elasticity and reduces vibrations. You can use it to treat water quality pump stations, water turbine units, and other equipment in water conservancy projects. Vibration reduction rubber sheets cut down equipment vibration and resonance. This boosts both efficiency and service life.

2. Performance evaluation

Performance evaluation covers oil resistance, mechanical properties, aging resistance, weather resistance, and environmental friendliness.

2.1 It resists oil well and can handle different oils and petroleum products. This helps it work better and last longer in oil-contaminated areas often seen in water projects.

2.2 It has very good mechanical properties such as tensile strength, tear strength, and compressive strength. These properties make rubber sheets stable and reliable. They can handle pressure, tension, and shear forces in water conservancy projects.

2.3 It has strong aging resistance. It lasts a long time in water conservancy projects without aging quickly. Its antioxidants and UV resistance help it stay smooth and strong in tough environments.

2.4 Weather resistance

It provides great weather resistance. Users can count on it for steady performance in different climates over time. It can handle high and low temperatures, humidity changes, and other weather factors. It won’t easily change shape or size. This helps it maintain stable dimensions and performance.

2.5 Environmental friendliness

It is eco-friendly. It has no harmful substances and meets environmental protection standards. Using this rubber sheet in water projects reduces pollution. It also protects the environment and supports sustainable development.

Hongwo Sealing Sheet

Hongwo Sealing Sheet